PRODUCTS

BLACK STRUTS

STANDARD STRUTS

COST EFFICIENT FLIGHT HERITAGE. Choose from 15 different sizes & performances and experience 8 weeks leadtime. Aluminium interface and composite tubing ensure low mass. Temperature range -45C to +55C.

Test results available on request.

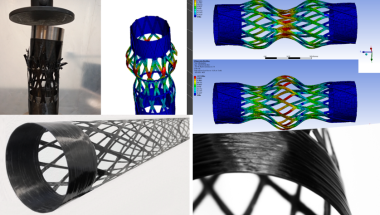

ANISOGRID

CUSTOM SPACE STRUCTURES

ONE-STOP-SHOP FOR SPACE STRUCTURES. Composites structures for Space applications: design, engineering, IN-HOUSE MANUFACTURING, test, verifications & integration support. Our many years of experience in Composites and Space ensure the most cost optimized solutions.

Filament winding, vacuum infusion, adhesive bonding, hand layup, machining

Thermal & mechanical FINITE ELEMENT ANALYSIS

CFRP/CORE PANELS

COST EFFICIENT SOLUTIONS either as THIN MONOLITH CFRP panels or CORE / CFRP panels.

SKINS: Carbon/Epoxy; CORES: honeycomb, foam and/or Soric; INSERTS: metallic or CFRP